Introduction: The Concrete Wastewater Challenge and Almasa’s Breakthrough

Concrete, the backbone of modern construction, comes with an environmental cost. The production of cement, precast structures, and other concrete products generates vast amounts of wastewater. This isn’t just any wastewater; it’s a complex mix of high pH levels, heavy metals like chromium, and a high concentration of total dissolved solids (TDS). Left untreated, this concrete wastewater can wreak havoc on ecosystems, contaminate water sources, and even pose risks to human health.

This is where Almasa Environmental Solutions enters the picture. They’ve pioneered a revolutionary acid-free technology that’s transforming how the industry deals with this problematic byproduct. In this comprehensive guide, we’ll dive deep into the world of concrete wastewater, the problems it poses, and how Almasa’s innovation is offering a sustainable solution.

The Dangers of Traditional Concrete Wastewater Treatment Methods

Traditional concrete wastewater treatment methods, while seemingly effective at first glance, are fraught with hidden dangers. These conventional approaches often rely heavily on hazardous chemicals, primarily acids, to neutralize the high pH levels found in wastewater. While this might temporarily address the alkalinity issue, it introduces a whole new set of problems.

The Chemical Cocktail:

- Worker Safety: Handling corrosive acids poses significant risks to the health and safety of workers involved in the treatment process. Protective gear is essential, but accidents can still happen, leading to burns, respiratory issues, and other health complications.

- Environmental Contamination: When these acids are used, they don’t magically disappear. They often end up in the treated water, which, if not carefully managed, can contaminate soil and water bodies. This secondary pollution can harm aquatic life, disrupt ecosystems, and even seep into groundwater.

- Corrosion of Infrastructure: Acids are notoriously corrosive. Over time, they can damage the very pipes, tanks, and equipment used in the treatment process, leading to costly repairs and replacements.

The Reverse Osmosis Roadblock:

In addition to chemical hazards, traditional methods often require reverse osmosis (RO) to address the high levels of total dissolved solids (TDS) in concrete wastewater. RO is a powerful filtration process, but it comes at a cost:

- Energy Consumption: RO systems are energy-intensive, requiring significant electricity to operate. This contributes to higher operating costs and a larger carbon footprint for the treatment facility.

- Maintenance Demands: RO membranes are delicate and prone to fouling. They require regular cleaning and maintenance to ensure optimal performance, adding to the overall operational expenses.

- Waste Generation: RO produces a concentrated waste stream (brine) that must be disposed of properly, presenting another environmental challenge.

The Environmental Toll:

When you combine the chemical hazards, energy consumption of RO, and the potential for secondary pollution, it becomes clear that traditional concrete wastewater treatment takes a heavy toll on the environment. The very process designed to clean water can end up contributing to pollution and resource depletion.

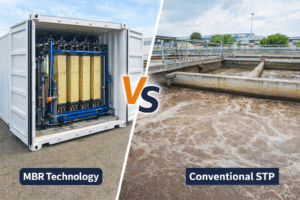

Table: Comparing Traditional vs. Almasa Concrete Wastewater Treatment

| Feature | Traditional Methods | Almasa’s Acid-Free Technology |

| Chemical Usage | High (acids and other chemicals) | None |

| Reverse Osmosis (RO) | Often required | Not required |

| Environmental Impact | High (secondary pollution, energy consumption) | Low |

| Operating Costs | High | Low (up to 40% reduction) |

| Worker Safety | Potential hazards due to chemical handling | Improved |

It’s evident that a more sustainable, safer, and cost-effective approach is needed. This is where Almasa’s acid-free technology steps in, offering a transformative alternative that addresses the shortcomings of traditional methods.

Almasa’s Game-Changing Solution: A Deep Dive

Almasa’s acid-free concrete wastewater treatment technology isn’t just an incremental improvement; it’s a paradigm shift. By ditching harmful chemicals and embracing innovation, Almasa has created a system that’s not only more sustainable but also more efficient and cost-effective.

The Science Behind Acid-Free Treatment

At the heart of Almasa’s technology lies a clever chemical process that leverages the power of carbon dioxide (CO2). Instead of using acids to neutralize the high pH of concrete wastewater, Almasa introduces CO2 gas into the water. This triggers a reaction that forms carbonic acid, a weak acid that effectively lowers the pH to a safe and stable level. This acid-free approach eliminates the risks associated with harsh chemicals while achieving the same desired outcome.

The Role of Carbon Capture, Utilization, and Storage (CCUS)

Almasa doesn’t just use CO2; they capture it. Their innovative Carbon Capture, Utilization, and Storage (CCUS) system is integrated into the wastewater treatment process. This means that the CO2 generated during cement production, which would otherwise be released into the atmosphere, is captured and used to treat the wastewater. This dual-purpose approach not only reduces greenhouse gas emissions but also turns a waste product into a valuable resource.

The Simplicity of the Process

Almasa’s concrete wastewater treatment process is remarkably straightforward:

- Collection: Wastewater from various concrete-related processes is collected in a central tank.

- CO2 Injection: CO2 gas is introduced into the wastewater, triggering the formation of carbonic acid and lowering the pH.

- Solids Separation: The treated water undergoes a series of filtration and separation steps to remove solids and other contaminants.

- Water Reuse or Discharge: The resulting clean water can be safely reused for various purposes or discharged into the environment without causing harm.

This streamlined process eliminates the need for complex chemical dosing systems, reduces energy consumption, and minimizes the risk of operational errors. It’s a testament to Almasa’s commitment to simplicity, efficiency, and sustainability.

The Benefits of Almasa Concrete Wastewater Treatment: A Win-Win for All

Almasa’s innovative approach to concrete wastewater treatment doesn’t just solve problems; it creates a cascade of benefits that ripple across environmental, economic, and safety domains.

Environmental Advantages: A Greener Tomorrow

- Significant Reduction in Greenhouse Gas Emissions: By capturing and utilizing CO2, Almasa actively contributes to the fight against climate change. The reduction in greenhouse gas emissions is substantial, aligning with global sustainability goals.

- Protection and Preservation of Precious Water Resources: Concrete wastewater, when treated with traditional methods, often cannot be safely reused or discharged. Almasa’s technology ensures that the treated water meets stringent quality standards, making it suitable for reuse in irrigation, industrial processes, or even replenishing local water sources. This reduces the demand for freshwater and helps conserve this vital resource.

- A Boost to the Circular Economy: The circular economy model aims to minimize waste and maximize resource utilization. Almasa’s CCUS technology embodies this principle by transforming a waste product (CO2) into a valuable asset for wastewater treatment. This approach reduces the need for virgin resources and promotes a more sustainable industrial ecosystem.

- Safeguarding Aquatic Ecosystems: Untreated concrete wastewater, with its high pH and contaminants, can wreak havoc on aquatic life. Almasa’s treated water is safe for discharge, protecting fish, plants, and other organisms that rely on healthy water systems.

Economic Benefits: Saving Money While Going Green

- Drastic Reduction in Operating Costs: Thanks to the elimination of harsh chemicals and the simplified treatment process, Almasa’s technology can slash operating costs by up to 40% compared to conventional methods. This translates to significant savings for businesses, making sustainability a financially sound choice.

- No More Expensive Reverse Osmosis: Traditional methods often necessitate reverse osmosis (RO) to remove TDS, a costly and energy-intensive process. Almasa’s technology eliminates the need for RO, further reducing expenses.

- Potential Revenue from CO2 Utilization: The captured CO2 isn’t just an environmental benefit; it’s a potential revenue stream. CO2 can be used in various industries, from food and beverage to manufacturing. By exploring these opportunities, businesses can turn a waste product into a valuable commodity.

Safety and Health: Protecting Workers and Communities

- Elimination of Chemical Hazards: Almasa’s acid-free approach removes the risks associated with handling corrosive chemicals. This creates a safer working environment for employees and minimizes the potential for accidents and injuries.

- Safe Water for All: The treated water produced by Almasa’s technology is safe for various applications, including irrigation and industrial use. This protects communities from the potential harm caused by contaminated water sources.

The Triple Bottom Line:

Almasa’s concrete wastewater treatment solution exemplifies the concept of the “triple bottom line,” where environmental, social, and economic considerations are all taken into account. It’s a win-win-win scenario that benefits businesses, the environment, and the communities they serve.

Case Study: Almasa’s Success at the Fujairah Cement Plant

To truly grasp the transformative power of Almasa’s technology, let’s take a closer look at a real-world example: the Fujairah Cement Plant in the United Arab Emirates. This large-scale cement production facility faced the typical challenges of concrete wastewater management, including high pH levels, chromium contamination, and elevated TDS.

The Challenge:

- High Wastewater Volume: The plant generated a significant amount of wastewater daily, requiring a robust and efficient treatment solution.

- Stringent Regulations: Environmental regulations in the UAE are strict, mandating that treated wastewater meet specific quality standards before discharge or reuse.

- Cost Considerations: The plant sought a cost-effective solution that would not only meet regulatory requirements but also reduce operational expenses.

The Almasa Solution:

Fujairah Cement Plant partnered with Almasa to implement their acid-free wastewater treatment system. The results were nothing short of remarkable:

- 95% Reduction in Chemical Usage: By eliminating the need for acids, the plant significantly reduced its chemical footprint, improving safety and minimizing environmental impact.

- 60% Decrease in Operating Costs: The streamlined process and elimination of RO resulted in a substantial decrease in operating costs, saving the plant a significant amount of money annually.

- Consistent Compliance: The treated wastewater consistently met and exceeded all regulatory requirements, ensuring the plant’s environmental compliance.

- Water Reuse: The high-quality treated water is now being reused for various purposes within the plant, further reducing freshwater consumption and promoting sustainability.

The Impact:

The successful implementation of Almasa’s technology at the Fujairah Cement Plant demonstrates the real-world effectiveness and benefits of this innovative approach. It’s a testament to how sustainable solutions can not only address environmental challenges but also improve operational efficiency and reduce costs.

This case study is just one example of how Almasa’s technology is making a difference in the concrete industry. By adopting this sustainable solution, companies can contribute to a cleaner environment, protect water resources, and improve their bottom line.

Frequently Asked Questions (FAQ)

Is Almasa’s technology proven and reliable?

Absolutely. Almasa’s acid-free concrete wastewater treatment technology has been rigorously tested and implemented in various real-world settings, including the Fujairah Cement Plant case study mentioned earlier. The technology is backed by a GCC (Gulf Cooperation Council) patent, demonstrating its innovation and effectiveness.

Can Almasa’s treated water be reused for other purposes?

Yes, one of the key advantages of Almasa’s technology is the high quality of the treated water. It consistently meets and often exceeds regulatory standards for various applications. Depending on the specific quality parameters and local regulations, the treated water can be reused for irrigation, industrial processes, dust suppression, or even to replenish local water sources.

How does Almasa’s solution compare to other “green” wastewater treatment options?

Almasa’s technology stands out due to its unique combination of acid-free operation, CCUS technology, and overall simplicity. Many other “green” solutions may still rely on some chemicals or complex processes. Almasa’s approach is not only environmentally friendly but also highly efficient and cost-effective, making it a compelling choice for businesses seeking sustainable wastewater treatment.

What is the lifespan of Almasa’s treatment systems?

Almasa’s treatment systems are designed for durability and longevity. With proper maintenance and care, they can last for many years, providing a reliable and sustainable solution for concrete wastewater treatment. The company also offers comprehensive support and maintenance services to ensure optimal performance and extend the lifespan of their systems.

What kind of support does Almasa offer to its clients?

Almasa is committed to providing comprehensive support to its clients throughout the entire project lifecycle. This includes:

- Consultation: Expert guidance on system design and implementation tailored to specific needs.

- Installation: Professional installation and commissioning of the treatment system.

- Training: Comprehensive training for plant operators on system operation and maintenance.

- Maintenance: Ongoing support and maintenance services to ensure optimal performance and longevity.

- Troubleshooting: Prompt assistance in resolving any technical issues that may arise.

Almasa’s commitment to customer satisfaction goes beyond simply providing technology; they strive to build long-term partnerships with their clients, ensuring their success in achieving sustainable wastewater management.

Looking Towards a Sustainable Future: Almasa’s Role in Shaping the Industry

Almasa’s innovative concrete wastewater treatment technology isn’t just about solving a current problem; it’s about shaping a more sustainable future for the construction industry. By embracing this solution, companies are taking a proactive step towards environmental responsibility and resource conservation.

Almasa’s Role in the Circular Economy

The circular economy model is gaining traction worldwide as a way to reduce waste, conserve resources, and create more sustainable industries. Almasa’s technology aligns perfectly with this model. By capturing and utilizing CO2, a byproduct of cement production, Almasa is closing the loop and minimizing waste. The treated water can be reused, and the captured CO2 has the potential to be repurposed for other applications, such as carbonation of concrete or use in greenhouses.

The Future of Concrete Wastewater Treatment

Almasa is at the forefront of innovation in concrete wastewater treatment. The company continues to research and develop new technologies to further improve efficiency, reduce costs, and expand the potential applications of treated water and captured CO2. As the construction industry faces increasing pressure to reduce its environmental impact, Almasa’s solutions are poised to play a pivotal role in shaping a more sustainable future.

How to Get Started with Almasa

If you’re ready to embrace a greener approach to concrete wastewater treatment, Almasa is here to help. Here’s how you can get started:

- Contact Almasa: Reach out to their team of experts to discuss your specific needs and challenges.

- Assessment: Almasa will conduct a thorough assessment of your wastewater generation and treatment requirements.

- Customized Solution: Based on the assessment, Almasa will design a tailored solution that meets your unique needs.

- Installation and Commissioning: Almasa will handle the installation and commissioning of the treatment system, ensuring it’s up and running smoothly.

- Training and Support: Almasa provides comprehensive training for your staff on system operation and maintenance, along with ongoing support to ensure optimal performance.

By partnering with Almasa, you’re not just investing in a wastewater treatment system; you’re investing in a sustainable future for your business and the planet.

Conclusion: A Sustainable Future for Concrete Wastewater Treatment

The construction industry, with its reliance on concrete, is at a crossroads. The traditional methods of dealing with concrete wastewater are no longer sustainable, posing risks to the environment, worker health, and operational efficiency. Almasa’s revolutionary acid-free technology offers a compelling alternative, a beacon of hope in a landscape often marred by pollution and waste.

By embracing Almasa’s solution, businesses can:

- Significantly reduce their environmental impact, contributing to a cleaner, healthier planet.

- Protect precious water resources and ensure their safe reuse.

- Lower operating costs and boost efficiency, making sustainability a financially sound decision.

- Improve worker safety by eliminating exposure to hazardous chemicals.

- Become leaders in sustainability and set a new standard for responsible practices within the construction industry.

The future of concrete wastewater treatment is acid-free, and Almasa is leading the charge. If you’re ready to take a bold step towards a more sustainable future, reach out to Almasa today. Let’s build a world where construction and environmental responsibility go hand in hand.