Monyin® MBR

Revolutionize wastewater treatment technology for domestic and industrial applications.

Table of Contents

Hollow Fiber Bio Membrane Reactor

A Membrane Bioreactor (MBR) merges conventional biological treatment with membrane filtration, delivering high-quality wastewater treatment in a compact system. It efficiently breaks down pollutants and separates contaminants, producing clean effluent suitable for reuse. Ideal for diverse applications from urban to industrial settings, MBRs offer significant advantages in water scarcity solutions, despite higher costs, by ensuring water reuse and superior effluent quality in a space-efficient design.

Advantages of Monyin® MBR

The Monyin hollow fiber membrane stands out for its ease of operation, maintenance, and startup, alongside its flexibility for modification and retrofitting, making it highly compatible with existing systems.

A Membrane Bioreactor (MBR) works like a high-tech filter for cleaning water. Imagine a combination of microscopic organisms and a special filter. These tiny organisms eat up impurities in the water, like bacteria and other pollutants. Then, the filter, which is like a fine mesh, catches the cleaned water while keeping the organisms and larger particles behind. This process makes the water incredibly clean and safe to use. It’s like having a team of natural cleaners and a super-fine strainer working together to purify

This demonstration visually represent the MBR process, where wastewater initially enters the system, undergoes biological treatment to break down pollutants, and then passes through a membrane filtration unit. The membrane’s fine pores effectively separate contaminants, including suspended solids, bacteria, and viruses, from the water. The result is the transformation of dirty sewage into clean water that appears significantly clearer

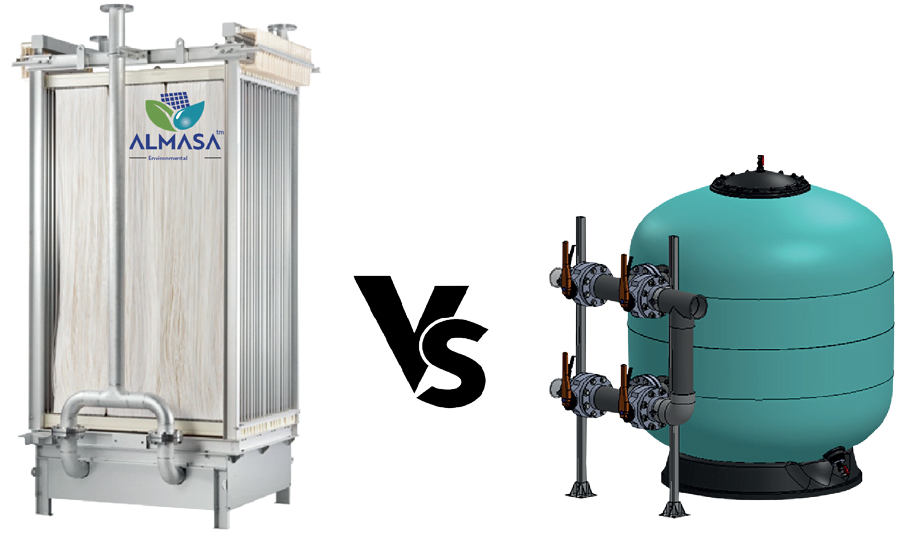

MBR Filtration Accuracy is 500 time more than Traditional Sand Filter

MBR Application

The filtration accuracy of Membrane Bioreactor technology is remarkably higher than that of traditional filtration methods, being 500 times more effective in separating contaminants from wastewater.

- Domestic wastewater treatment

- Greywater treatment

- Residential and small-scale systems

- Slaughter House

- Food Processing Industry

- Dairy Farms

- Poultry Farms

- Textile Industry

- Oil and gas industry

Why UAE Made Almasa Monyin® MBR

MBR water treatment produces high-quality water perfect for everything from farming to safe drinking water, offering a versatile solution for water needs.

Almasa Environmental Solutions has taken a pioneering step in the Middle East by launching the UAE’s first Membrane Bioreactor (MBR) manufacturing facility. This initiative addresses the region’s challenges with the adoption of advanced wastewater treatment technologies, primarily due to the high costs of imported systems and the lack of local services and maintenance support.

By producing every component locally, Almasa has made significant strides in making MBR technology more accessible and affordable in the region. Their commitment to quality and reliability is supported by a dedicated team of highly trained technical staff, ensuring the continuous optimal performance of their systems.

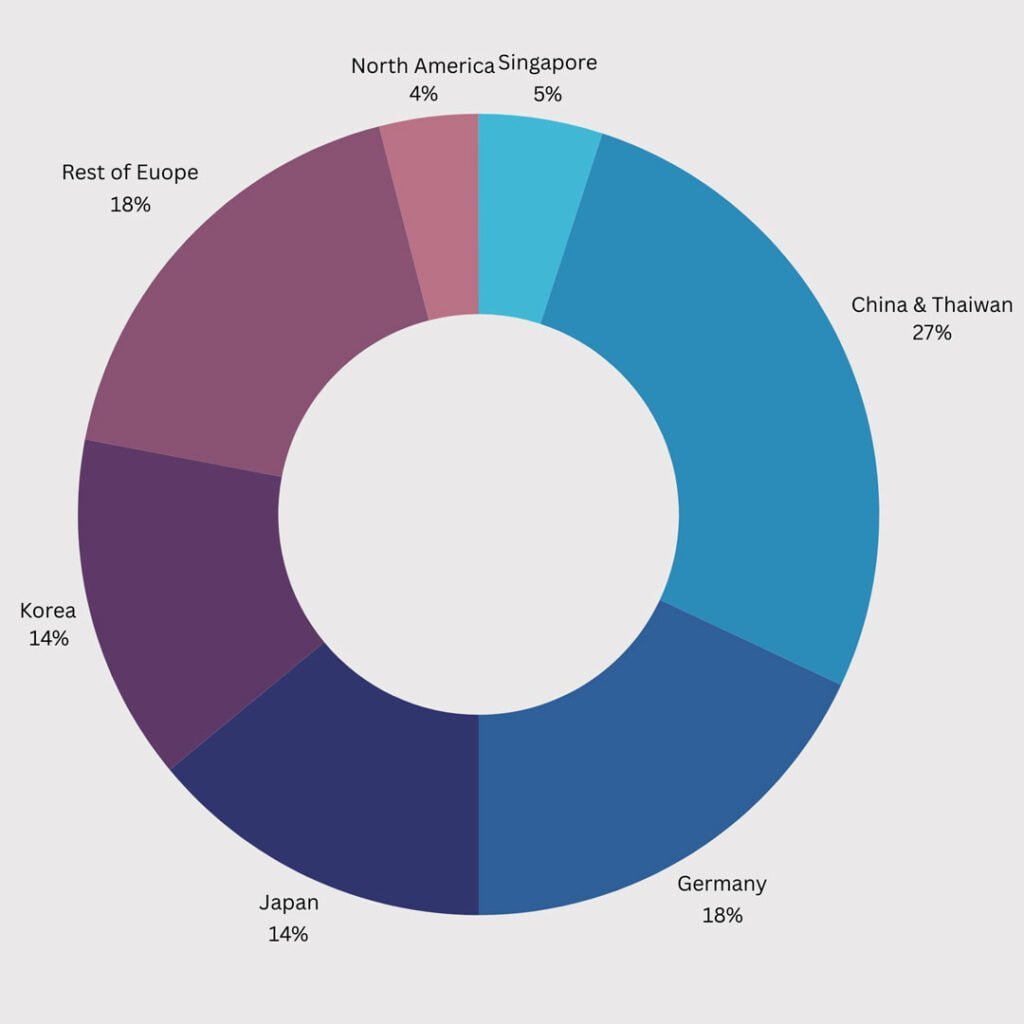

Worldwide Producers of MBR

Contact Us

Share:

More Posts

Almasa Environmental at WaterTech China 2025 – A Successful Showcase

Almasa Environmental proudly participated in WaterTech China 2025, held from June 4–6, 2025, at the National Exhibition and Convention Center (Hongqiao), Shanghai. This globally renowned

Maximizing Efficiency: Revolutionizing Wastewater Treatment in Minimal Space

Introduction As urban spaces grow increasingly crowded, the challenge of managing essential infrastructure like sewage treatment plants within limited areas has become more pressing than

Biodiversity: The Best Path To Sustainability – Part 2

In the quest for sustainability, motivations vary widely among individuals. Some are driven by a desire to leave a lasting legacy, while others focus on

From Waste to Wealth: How Sewage Treatment Plants Are Revolutionizing Sustainability

Picture this: a sprawling metropolis, its streets perpetually clogged with tanker trucks hauling sewage across town. The incessant rumble of engines, the acrid smell of