Table of Contents

The Membrane Bioreactor (MBR) technology has emerged as a cutting-edge solution for wastewater treatment, combining biological processes with advanced membrane filtration. While the technical advantages of MBR systems are widely recognized, understanding their economic implications is crucial for municipalities and industries considering their implementation. This article explores the financial aspects of adopting MBR technology, focusing on initial costs, operational expenses, potential savings, and long-term benefits.

Initial Investment Costs

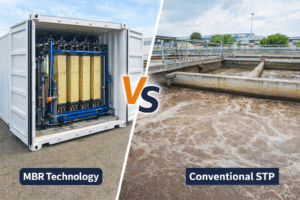

The initial investment in MBR systems can be significant compared to conventional wastewater treatment methods. Key factors contributing to the startup costs include:

Equipment and Technology:

MBR systems require specialized membranes and bioreactor designs, which can be more expensive than traditional treatment technologies. The choice between different types of membranes (microfiltration vs. ultrafiltration) can also impact costs.

Infrastructure Modifications:

Existing treatment plants may need substantial modifications to accommodate MBR systems. This can involve upgrading structures, piping, and controls to integrate the new technology.

Installation and Commissioning:

The installation process for MBR systems can be complex, requiring skilled labor and expertise. Commissioning these systems to ensure they operate efficiently also adds to upfront costs.

Operational Expenses

While MBR systems often entail higher initial investments, their operational expenses can be more favorable in the long run:

Energy Consumption:

MBR systems typically have lower energy demands than traditional processes due to their compact design and efficient operation. This can lead to reduced electricity costs over time.

Chemicals and Maintenance:

MBR technology generally requires fewer chemicals for coagulation and flocculation, resulting in lower chemical costs. Additionally, the advanced design of MBR systems often leads to reduced maintenance needs, further decreasing operational expenses.

Sludge Management:

MBR systems produce less sludge compared to conventional methods. This reduction in sludge not only lowers disposal costs but also minimizes the environmental impact associated with sludge treatment and disposal.

Potential Savings and Economic Benefits

Implementing MBR technology can lead to significant economic advantages:

High-Quality Effluent

The superior effluent quality produced by MBR systems can open up new opportunities for water reuse. Treated water can be repurposed for irrigation, industrial processes, or even potable applications after additional treatment, generating economic benefits through reduced reliance on freshwater sources.

Reduced Land Requirements:

MBR systems are more compact than traditional treatment methods, allowing facilities to occupy less space. This can be particularly advantageous in urban areas where land costs are high, potentially reducing the need for land acquisition and associated expenses.

Increased Regulatory Compliance:

MBR technology often enables facilities to meet stringent regulatory standards for effluent discharge. This can prevent costly fines and penalties associated with non-compliance and protect public health.

Long-Term Resilience:

As water scarcity issues intensify globally, investing in advanced treatment technologies like MBR can enhance a community’s resilience to environmental challenges, potentially attracting businesses and investments looking for sustainable operations.

Case Studies and Real-World Examples

Several municipalities and industries have successfully implemented MBR systems, showcasing their economic viability:

Municipal Wastewater Treatment:

Cities that have adopted MBR technology often report lower operational costs and improved effluent quality. For example, a city in California saw a reduction in energy consumption by up to 30% after switching to MBR, leading to significant cost savings over time.

Industrial Applications:

Industries like food processing and pharmaceuticals have turned to MBR systems to handle complex wastewater streams. One facility in Europe reported a 40% reduction in sludge disposal costs after implementing MBR technology, improving their bottom line.

Conclusion

While the initial investment in Membrane Bioreactor systems may be higher than traditional wastewater treatment methods, the long-term economic benefits can be substantial. Lower operational costs, reduced sludge production, and opportunities for water reuse can lead to significant savings and a positive return on investment. As global water challenges continue to grow, MBR technology presents a viable and economically sound solution for sustainable wastewater management. By understanding and addressing the economic aspects of MBR implementation, municipalities and industries can make informed decisions that align with both environmental and financial goals.