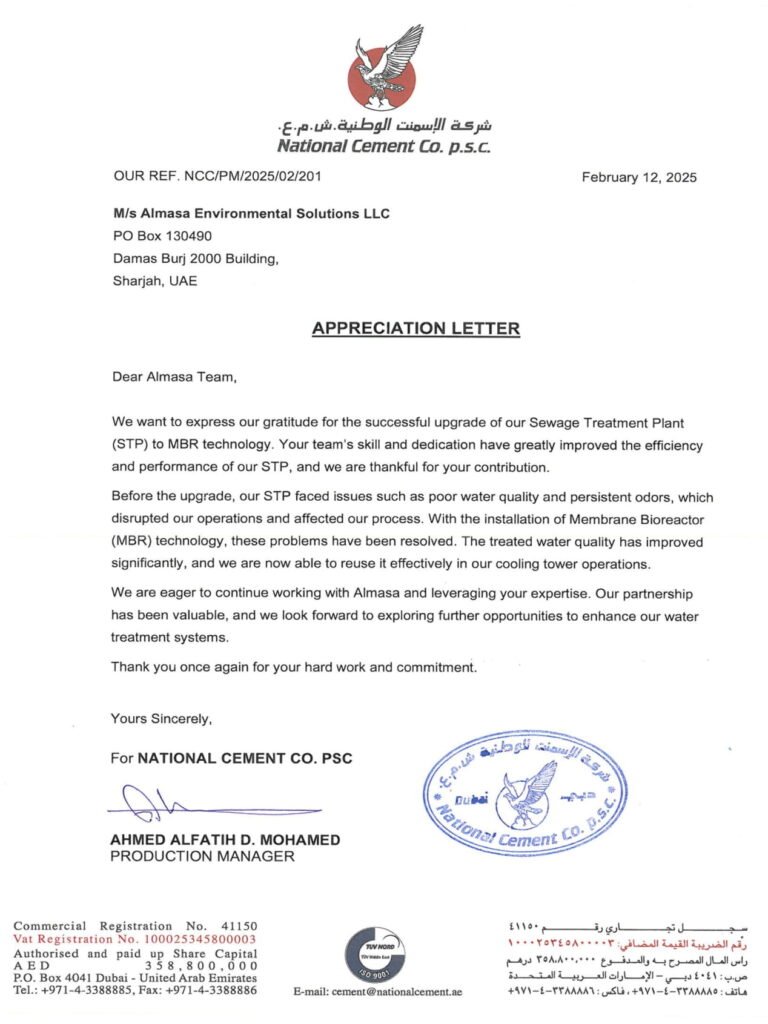

Successful STP Upgrade to MBR Technology for National Cement Co.

At Almasa Environmental Solutions, we are proud to help industries overcome wastewater challenges with reliable and sustainable solutions. A recent success story comes from National Cement Co. p.s.c., where we completed a sewage treatment plant (STP) upgrade to MBR technology in February 2025.

The client expressed deep appreciation for the project, noting how the upgrade resolved long-standing issues of poor water quality and persistent odor emissions. With the new system, the treated water quality improved dramatically and is now being effectively reused in cooling tower operations — a strong testament to the value of our advanced MBR systems.

Why an STP Upgrade Was Needed

Prior to the upgrade, the facility faced multiple challenges:

-

Poor water quality from the existing system, making reuse impractical

-

Unpleasant odor emissions affecting both operations and surrounding areas

-

Inefficient processes leading to higher operational costs

These issues limited the plant’s ability to reuse wastewater and increased its reliance on fresh water supplies. For an industrial facility like National Cement Co., where cooling towers consume significant amounts of water, finding a sustainable alternative was critical.

The Almasa Solution – MBR Technology

Our engineering team carried out a complete upgrade of the sewage treatment plant to MBR (Membrane Bioreactor) technology. The solution provided:

-

Superior effluent quality that meets the stringent requirements for cooling tower reuse

-

Odor elimination, creating a cleaner and healthier working environment

-

Automated operation, reducing the need for constant manual oversight

-

Long-term reliability, ensuring consistent performance for industrial needs

The result is a robust, cost-effective, and eco-friendly treatment system tailored for industrial applications.

Key Benefits for National Cement Co.

The appreciation letter highlights several benefits that showcase the effectiveness of the project:

1. Improved Water Quality

The MBR system consistently delivers high-quality treated water, making it suitable for reuse in demanding applications like cooling towers.

2. Elimination of Odor Issues

The persistent odors from the old system have been completely resolved, improving site conditions and compliance with environmental standards.

3. Water Reuse in Cooling Towers

By recycling treated wastewater for cooling purposes, the company significantly reduces its freshwater consumption and associated costs.

4. Operational Efficiency

The automated nature of the MBR plant reduces manpower needs and ensures smooth, uninterrupted operation.

5. Sustainability and Cost Savings

With water reuse now integrated into daily operations, National Cement Co. benefits from long-term cost reductions and a smaller environmental footprint.

Case Study Snapshot

-

Client: National Cement Co. p.s.c.

-

Date: February 12, 2025

-

Project: Upgrade of Sewage Treatment Plant (STP) to MBR Technology

-

Application: Treated water reuse in cooling towers

-

Benefits: Improved water quality, odor removal, water reuse, efficiency, sustainability

Industrial Water Reuse – A Growing Need

In the cement industry and other heavy industries, cooling towers account for a large percentage of water use. With rising water costs and increasing sustainability pressures, wastewater recycling is becoming essential.

The National Cement project demonstrates how an STP upgrade to MBR technology can provide a direct solution, turning wastewater from a liability into a valuable resource for industrial reuse.

Supporting UAE’s Sustainability Goals

The UAE’s industrial sector is under growing pressure to adopt sustainable water practices in line with national environmental goals. By reusing wastewater in cooling towers, National Cement Co. not only saves costs but also contributes to the country’s broader water conservation efforts.

Almasa’s expertise in STP upgrade to MBR technology positions us as the trusted partner for companies seeking both efficiency and compliance in sewage treatment.

Why Choose Almasa for Industrial Wastewater Solutions

Our clients, including National Cement Co., rely on us because we provide:

-

Tailored solutions designed for industrial challenges

-

Proven expertise in MBR and advanced wastewater systems

-

Reliable performance with automation and ease of operation

-

Sustainability-driven designs that align with corporate and national goals

Partnership and Future Collaboration

The client’s appreciation confirms the value and reliability of our solutions. With water reuse now supporting cooling tower operations, National Cement Co. has strengthened both efficiency and sustainability.

At Almasa Environmental Solutions, we are committed to supporting future upgrades, optimizations, and expansions to ensure lasting value for our partners.

Call to Action

If your facility faces challenges with poor wastewater quality, odor issues, or high water costs, it may be time to consider an STP upgrade to MBR technology. Contact Almasa Environmental Solutions today to discuss a customized solution for your operations.