The world is facing a growing challenge: how to manage the massive amounts of wastewater generated by our homes, industries, and cities. The need for efficient, sustainable, and innovative treatment solutions has never been more urgent. Enter Membrane Bioreactors (MBR), a cutting-edge technology that’s revolutionizing the way we clean and reuse water.

MBR systems offer a powerful combination of biological treatment and membrane filtration, resulting in exceptionally clean water that can be safely returned to the environment or even repurposed for various uses. If you’re curious about this game-changing technology, you’re in the right place. We’ll delve into the intricacies of MBR, its benefits, applications, and the pioneering role of companies like Almasa Environmental Solutions in shaping the future of wastewater treatment.

Get ready to explore the exciting world of MBR and discover how it’s transforming the way we manage one of our most precious resources – water.

What is a Membrane Bioreactor (MBR)?

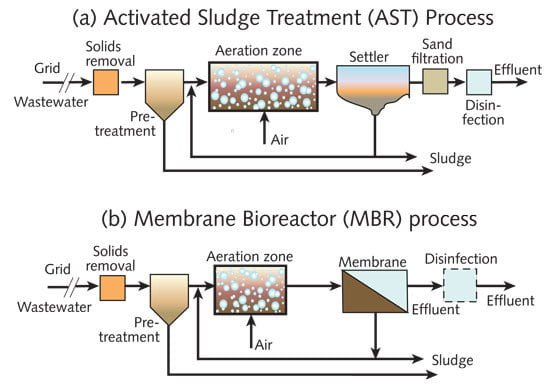

A Membrane Bioreactor (MBR) is a cutting-edge wastewater treatment system that combines two powerful processes: biological treatment and membrane filtration. This dynamic duo works together to produce exceptionally clean water, often exceeding the quality achieved by traditional methods.

How MBR Systems Work

At its core, an MBR system has two main components:

- Bioreactor: This is where the magic of biological treatment happens. The bioreactor houses a diverse community of microorganisms that feast on the organic pollutants in the wastewater. These tiny helpers break down the harmful substances, converting them into less harmful byproducts.

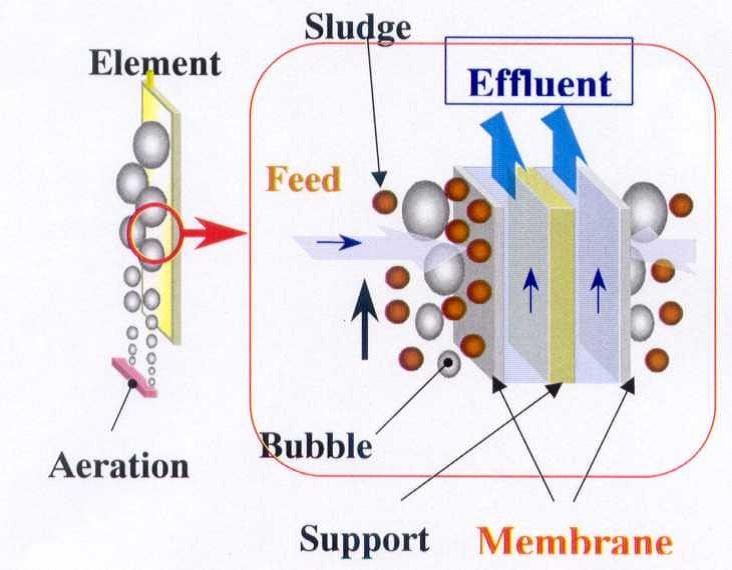

- Membrane Module: This is the filtration powerhouse. The membrane module consists of thousands of tiny pores that act like a super-fine sieve. As the wastewater flows through the membrane, these pores trap solids, bacteria, and other unwanted particles, allowing only clean water to pass through.

The MBR Process in a Nutshell

- Influent: Raw wastewater enters the bioreactor.

- Biological Treatment: Microorganisms in the bioreactor break down the organic pollutants.

- Membrane Filtration: The treated water flows through the membrane module, where solids and other impurities are removed.

- Treated Effluent: The clean, filtered water is ready for reuse or discharge.

Types of MBR Systems

There are two main types of MBR configurations:

- Submerged MBR: In this setup, the membrane modules are submerged directly in the bioreactor tank.

- Sidestream MBR: Here, the membrane modules are housed in a separate tank, and the treated water from the bioreactor is pumped through them.

Both types have their advantages and disadvantages, and the best choice depends on the specific needs of the wastewater treatment plant.

Almasa’s Expertise in MBR Technology

Almasa Environmental Solutions is a pioneer in MBR technology, offering a wide range of MBR solutions to meet the diverse needs of their clients. Their expertise covers submerged MBR system , ensuring that they can provide the most suitable solution for each specific application. Almasa’s commitment to innovation and sustainability makes them a trusted partner for wastewater treatment projects across various industries . Also that they called it Monyin MBR System.

Why Choose Membrane Bioreactors (MBR) for Wastewater Treatment?

Membrane Bioreactors (MBR) have rapidly gained popularity in the wastewater treatment industry, and for good reason. They offer a multitude of advantages over traditional treatment methods, making them a compelling choice for a variety of applications.

Advantages of MBR Technology

- Better Design: we use hollow fiber membrane design. And it’s a new better design.

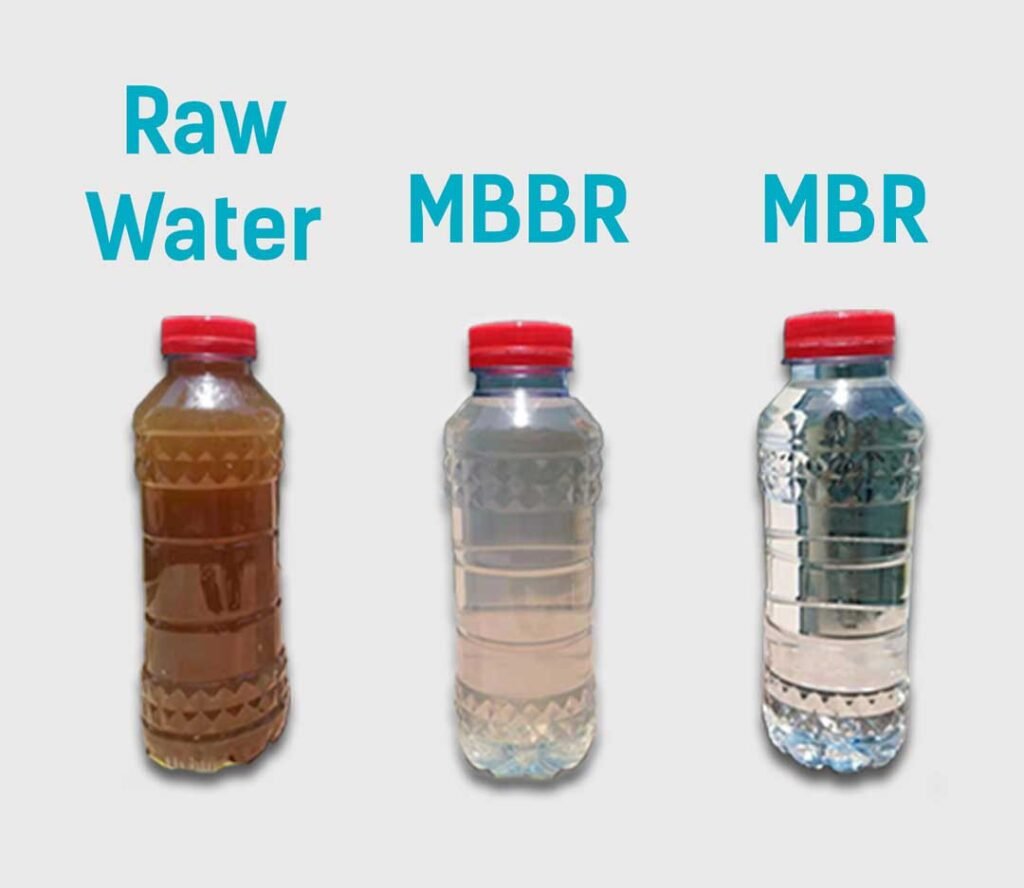

- Superior Effluent Quality: MBRs consistently produce high-quality treated water that often surpasses regulatory standards. This is due to the fine pore size of the membranes the size is extemley small 100-nanometer pores, which effectively remove suspended solids, bacteria, viruses, and other pollutants. The resulting effluent is suitable for a wide range of reuse applications, including irrigation and industrial processes.

- Compact Footprint: MBR plants require significantly less space than conventional wastewater treatment systems. This is a major advantage in urban areas or locations with limited space availability. The compact design also translates to lower construction costs and easier integration into existing infrastructure.

- Modular Design: MBR systems are highly scalable and adaptable. They can be easily expanded or modified to accommodate changing treatment needs. This flexibility makes them a practical choice for both small and large-scale wastewater treatment plants.

- Reduced Sludge Production: The membrane filtration process in MBRs results in a higher concentration of biomass in the bioreactor. This leads to a significant reduction in sludge production, which lowers disposal costs and minimizes the environmental impact of the treatment process.

- Water Reuse Potential: The high-quality effluent produced by MBRs opens up exciting possibilities for water reuse. This can help to alleviate water scarcity issues and contribute to a more sustainable water management approach. MBR-treated water can be used for irrigation, industrial processes, toilet flushing, and even groundwater recharge.

MBR vs. Traditional Wastewater Treatment

| Feature | Membrane Bioreactor (MBR) | Conventional Activated Sludge (CAS) |

| Effluent Quality | Superior | Lower |

| Footprint | Compact | Larger |

| Sludge Production | Reduced | Higher |

| Water Reuse Potential | High | Limited |

| Operational Complexity | Moderate | Lower |

| Energy Consumption | Moderate | Lower |

As the table illustrates, MBRs offer several key advantages over traditional activated sludge systems. However, it’s important to note that MBRs typically require higher operational expertise and energy consumption compared to conventional methods.

Almasa Environmental Solutions: Leading the Way in MBR Technology

Almasa Environmental Solutions is a pioneer in the field of wastewater treatment, specializing in innovative and sustainable solutions. With a strong focus on Membrane Bioreactor (MBR) technology, Almasa has established itself as a leader in the Middle East and North Africa (MENA) region, providing cutting-edge solutions for various industries and applications.

Introduction to Almasa

Almasa Environmental Solutions is committed to delivering advanced wastewater treatment technologies that promote environmental stewardship and resource conservation. Their team of experts brings together extensive experience in engineering, design, and project management, ensuring seamless implementation and optimal performance of their MBR systems.

Almasa’s MBR Services

Almasa offers a comprehensive range of MBR services, catering to the diverse needs of their clients:

- Containerized MBR Systems: These compact and modular systems are ideal for small to medium-sized projects, offering a plug-and-play solution that is easy to install and maintain.

- Custom-Designed MBR Plants: Almasa also designs and builds custom MBR plants for larger projects, tailoring the design to the specific requirements and constraints of each site.

- Upgrade existing treatment plant: we do upgrades of existing treatment method with our higher technology facilities.

- MBR Installation, Commissioning, and Maintenance: Almasa’s experienced team provides full support throughout the project lifecycle, from initial installation and commissioning to ongoing maintenance and optimization.

- Technical Support and Training: Almasa offers comprehensive technical support and training to their clients, ensuring that they have the knowledge and skills necessary to operate and maintain their MBR systems effectively.

Unique Features of Almasa’s MBR Systems

Almasa’s MBR systems are designed with several unique features that enhance their performance and efficiency:

- Energy Efficiency: Almasa utilizes energy-efficient components and designs, minimizing the energy consumption of their MBR systems. This helps to reduce operational costs and minimize the environmental impact of the treatment process.

- Advanced Monitoring and Control Systems (SCADA system): Almasa’s MBR systems are equipped with state-of-the-art monitoring and control systems, allowing for real-time monitoring of system performance and early detection of any potential issues. This ensures optimal operation and minimizes downtime.

Case Study: Almasa’s MBR Solution for a Residential Community

Almasa recently implemented a containerized MBR system for a residential community facing water scarcity issues. The MBR system was designed to treat the community’s wastewater and produce high-quality reclaimed water for irrigation and landscaping purposes. The project was a resounding success, with the MBR system consistently producing high-quality effluent that met the stringent standards for reuse. The community was able to significantly reduce its reliance on freshwater resources, contributing to a more sustainable water management approach.

Applications of Membrane Bioreactors (MBR)

The versatility and efficiency of Membrane Bioreactors (MBR) make them a sought-after solution for a wide array of wastewater treatment applications across different sectors. Let’s delve into some of the key areas where MBRs are making a significant impact:

Municipal Wastewater Treatment

In urban areas, where space is often at a premium and discharge regulations are stringent, MBRs offer a compact and effective solution for treating municipal wastewater. Their superior effluent quality ensures that treated water meets or exceeds the strictest environmental standards, making it safe for discharge into rivers, lakes, or other water bodies. Additionally, the ability to reclaim high-quality water for reuse in irrigation, industrial processes, or toilet flushing makes MBRs a valuable tool for sustainable water management in cities.

Industrial Wastewater Treatment

Many industries generate wastewater with complex and varying compositions, making treatment a challenging task. MBRs are well-suited for this challenge, as they can handle a wide range of pollutants and produce consistently high-quality effluent. Industries such as food processing, textiles, pharmaceuticals, and petrochemicals are increasingly turning to MBRs for their wastewater treatment needs. The ability to reuse treated water for process applications or cooling towers can also result in significant cost savings for industries.

Decentralized Wastewater Treatment

In remote locations or smaller communities where centralized treatment systems are not feasible, MBRs offer a decentralized solution. Their compact footprint and modular design make them easy to transport and install in remote areas. MBRs can be used to treat wastewater from hotels, resorts, hospitals, or small communities, providing a reliable and efficient solution for wastewater management in these settings.

Water Reuse

The high-quality effluent produced by MBRs opens up exciting possibilities for water reuse. This can be particularly beneficial in regions facing water scarcity or where water conservation is a priority. MBR-treated water can be used for:

- Irrigation: Providing a sustainable source of water for agriculture and landscaping.

- Industrial Processes: Replacing freshwater in various industrial applications, such as cooling towers and boiler feedwater.

- Toilet Flushing: Reducing the demand for freshwater in commercial and residential buildings.

- Groundwater Recharge: Replenishing depleted aquifers and improving water security.

Almasa Environmental Solutions recognizes the importance of water reuse and works closely with clients to develop tailored MBR solutions that maximize the potential for water reclamation. Their expertise in designing and implementing MBR systems for specific reuse applications ensures that clients can reap the full benefits of this valuable resource.

The Future of MBR Technology and Wastewater Management

The future of wastewater treatment is undeniably intertwined with the continued advancement and adoption of Membrane Bioreactor (MBR) technology. As global water scarcity concerns intensify and environmental regulations become more stringent, MBRs are poised to play a pivotal role in shaping a more sustainable and resilient water future.

Emerging Trends in MBR Technology

The field of MBR technology is constantly evolving, with several exciting trends on the horizon:

- Hybrid MBR Systems: These innovative systems combine MBR technology with other treatment processes, such as activated carbon filtration or ozone treatment, to achieve even higher levels of purification and remove specific contaminants.

- Energy-Efficient Designs: Researchers and engineers are developing new MBR designs that minimize energy consumption, making the technology more sustainable and cost-effective. This includes optimizing membrane materials, aeration systems, and pumping configurations.

- Smart Monitoring and Control: The integration of artificial intelligence (AI) and machine learning (ML) into MBR systems is enabling more sophisticated monitoring and control. This allows for real-time optimization of system performance, predictive maintenance, and early detection of potential issues, further enhancing the efficiency and reliability of MBR plants.

Environmental Impact of MBRs

MBR technology has a significant positive impact on the environment. By producing high-quality effluent that can be safely discharged or reused, MBRs help to protect water resources and minimize pollution. The reduced sludge production also translates to lower environmental impact from sludge disposal. Additionally, the ability to reclaim water for various uses helps to conserve freshwater resources and reduce the strain on natural ecosystems.

Cost Considerations of MBRs

While the initial investment in an MBR system can be higher than that of traditional treatment methods, the long-term operational and maintenance costs are often lower. The reduced sludge production, lower chemical consumption, and potential for water reuse can result in significant cost savings over time. Moreover, the environmental benefits and regulatory compliance advantages of MBRs add to their overall value proposition.

Almasa’s Vision for the Future of MBR Technology

Almasa Environmental Solutions is committed to driving the future of MBR technology and wastewater management. They are constantly investing in research and development to enhance the performance, efficiency, and sustainability of their MBR systems. Almasa’s vision is to provide innovative and customized MBR solutions that empower clients to achieve their wastewater treatment goals while minimizing their environmental footprint.

As a pioneer in the MENA region, Almasa is well-positioned to lead the way in the adoption and advancement of MBR technology. Their expertise, commitment to innovation, and focus on sustainability make them a valuable partner for any organization seeking a cutting-edge and environmentally responsible solution for their wastewater treatment needs.

Conclusion

Membrane Bioreactors (MBR) are undoubtedly a game-changer in the field of wastewater treatment. Their ability to produce high-quality effluent, combined with their compact footprint, modular design, and potential for water reuse, makes them a compelling solution for a wide range of applications. As the world grapples with increasing water scarcity and stricter environmental regulations, MBRs offer a sustainable and efficient way to manage wastewater and ensure the availability of clean water for future generations.

Companies like Almasa Environmental Solutions are at the forefront of this technological revolution, providing innovative and customized MBR solutions that cater to the specific needs of their clients. Their commitment to research, development, and sustainability ensures that their MBR systems are not only technologically advanced but also environmentally responsible.

If you’re considering a wastewater treatment solution for your municipality, industry, or community, Membrane Bioreactors are worth serious consideration. Their numerous advantages and potential for water reuse make them a wise investment in the long run. With companies like Almasa leading the way, the future of wastewater treatment looks brighter and more sustainable than ever before.

Are you ready to explore how MBR technology can transform your wastewater treatment process? Contact Almasa Environmental Solutions today to learn more about their cutting-edge MBR solutions and how they can help you achieve your wastewater treatment goals.