MBR Technology UAE: The Shift Away from Conventional STPs

MBR technology UAE adoption is accelerating as industries, developers, and municipalities move away from conventional sewage treatment plants (STPs). Traditional treatment systems are increasingly unable to meet modern demands for water reuse, space efficiency, and stricter environmental regulations.

Membrane Bioreactor (MBR) technology is emerging as the preferred solution, offering superior treatment performance, operational reliability, and long-term sustainability.

Understanding Conventional STPs and Their Limitations

Conventional STPs typically rely on primary settling, biological treatment, secondary clarification, and sand filtration. While these systems have been used for decades, they face several challenges in today’s operating environment:

Large land footprint

Inconsistent effluent quality

Limited reuse capability

Higher sludge production

Difficulty meeting tightening discharge norms

As water scarcity intensifies in the UAE, these limitations have become more pronounced.

What Is MBR Technology and Why It Matters

MBR technology combines biological wastewater treatment with membrane filtration, replacing conventional secondary clarifiers and sand filters. The membrane acts as a physical barrier, ensuring near-complete removal of suspended solids, bacteria, and pathogens.

This makes MBR systems ideal for applications where high-quality treated water and compact design are essential.

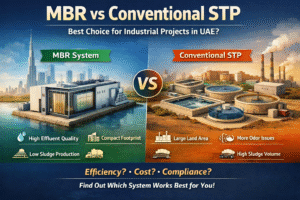

MBR vs Conventional STP: Key Differences

1. Effluent Quality

MBR systems deliver consistently superior effluent quality compared to conventional STPs. The membrane filtration ensures crystal-clear treated water suitable for reuse in irrigation, cooling towers, and industrial applications.

2. Footprint and Space Efficiency

MBR technology requires significantly less space. By eliminating large clarifiers and tertiary filtration units, MBR systems are ideal for urban developments, retrofits, and constrained sites.

3. Operational Stability

Conventional STPs often struggle with fluctuating loads. MBR systems maintain stable performance even under variable flow and load conditions, making them more reliable.

Why MBR Technology Is Replacing Conventional STPs in the UAE

1. Stricter Environmental Regulations

Authorities across the UAE are enforcing tighter discharge and reuse standards. MBR technology meets and exceeds these requirements without extensive tertiary treatment.

2. Water Reuse Is No Longer Optional

With water scarcity a critical concern, reuse has become essential. MBR-treated water supports safe and reliable reuse, reducing dependence on freshwater sources.

3. Compact Design for Urban Development

As land availability decreases, compact treatment systems are essential. MBR technology allows high-capacity treatment within smaller footprints.

4. Easier STP Upgrades

Existing conventional STPs can be upgraded to MBR systems without full replacement, making MBR an attractive retrofit solution.

5. Lower Long-Term Operating Costs

Although initial investment may be higher, MBR systems reduce costs related to chemicals, sludge handling, and regulatory non-compliance over time.

Best Wastewater Treatment Technology for the Future

When evaluating the best wastewater treatment technology, decision-makers increasingly favor MBR systems due to their balance of performance, sustainability, and adaptability.

MBR technology supports:

Long-term compliance

Reduced environmental impact

Consistent reuse-quality water

Future-ready plant design

Almasa’s Role in Advancing MBR Technology in the UAE

Almasa Environmental Solutions has played a pioneering role in advancing MBR technology UAE, including the establishment of local MBR membrane manufacturing.

Through its Monyin® MBR membranes, Almasa delivers:

Locally manufactured solutions

Faster delivery timelines

Customized system design

Reliable after-sales service

With over 600+ projects across the GCC, Almasa combines technical expertise with deep regional understanding.

Why Industries Are Choosing MBR Over Conventional STPs

Industries across the UAE are upgrading to MBR systems to:

Improve environmental performance

Achieve water reuse targets

Reduce operational risks

Ensure long-term regulatory compliance

MBR technology is no longer a premium option it is becoming the industry standard.

Is It Time to Upgrade Your STP?

If you are operating a conventional STP and facing space constraints, inconsistent effluent quality, or regulatory pressure, upgrading to MBR technology UAE could be the most effective solution.

Contact Almasa Environmental Solutions today to evaluate your STP and explore MBR upgrade options tailored to your facility.

Why is MBR technology preferred over conventional STPs in the UAE?

MBR technology is preferred over conventional STPs in the UAE because it delivers consistently higher effluent quality, requires a smaller footprint, and supports water reuse. With stricter environmental regulations and growing water scarcity, MBR systems provide a future-ready solution that conventional STPs struggle to achieve.

What is the main difference between MBR and conventional sewage treatment plants?

The main difference between MBR and conventional sewage treatment plants is membrane filtration. MBR systems use membranes to physically separate solids and microorganisms, while conventional STPs rely on gravity settling and sand filtration, which results in lower and less consistent effluent quality.

Is MBR technology suitable for upgrading existing STPs?

Yes, MBR technology is highly suitable for upgrading existing STPs. Many conventional sewage treatment plants in the UAE can be retrofitted with MBR membranes without major civil modifications, improving performance while minimizing downtime and cost.

Is MBR technology more expensive than conventional STPs?

While the initial capital cost of MBR technology may be higher, the long-term operational cost is often lower. MBR systems reduce chemical usage, sludge handling costs, land requirements, and the risk of regulatory penalties, making them cost-effective over the plant lifecycle.

What industries benefit most from MBR technology in the UAE?

Industries such as hospitality, manufacturing, residential developments, industrial facilities, labor camps, and commercial complexes benefit most from MBR technology due to its compact design, stable operation, and ability to produce reuse-quality treated water.

Who provides MBR technology solutions in the UAE?

Almasa Environmental Solutions is a leading provider of MBR technology in the UAE, offering locally manufactured MBR membranes, system design, installation, upgrades, and long-term technical support across the GCC.

Where can I find official wastewater reuse or discharge guidelines in the UAE?

Official wastewater reuse and discharge guidelines in the UAE are issued by government authorities such as municipalities and environmental regulators, which define effluent quality requirements for treated wastewater reuse and disposal.