Effluent Treatment Plant

Compact & Sustainable Effluent Treatment for Industrial Wastewater

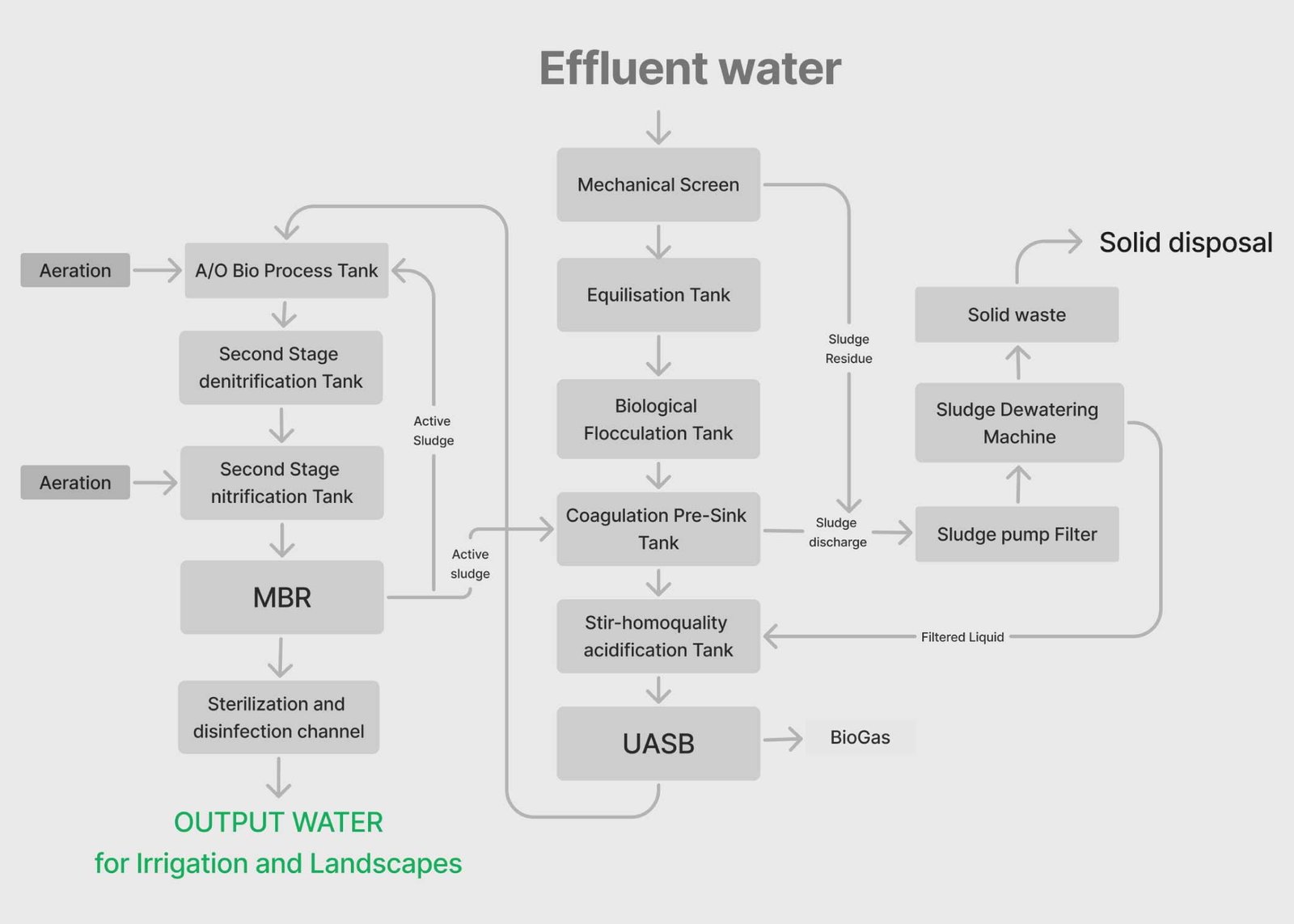

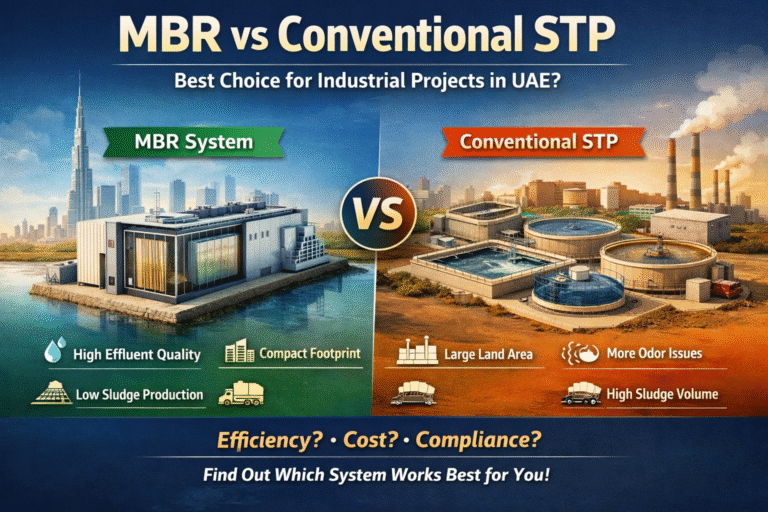

Effluent wastewater treatment through Membrane Bioreactors (MBRs) integrates biological processes to significantly reduce high Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) levels, producing clarified, low-COD, and low-BOD water suitable for discharge or reuse while minimizing the environmental impact. MBRs provide efficient and compact solu- tions for tackling elevated organic content in wastewater.

Why Choose Our Effluent Treatment Plant?

- Advanced Monyin® MBR Technology

- Significant Reduction in COD and BOD

- Automated Operation with SCADA

- Space Saving Compact Design

Industrial Applications

Effluent Treatment Plants (ETPs) play a critical role in managing and treating wastewater from various sources to ensure it meets environmental standards before being released back into the environment or reused. The usage and applications of ETPs are diverse and span multiple industries and sectors

Textile Industry: Treatment of dyeing and printing wastewater, which contains a variety of chemicals and colorants, to remove harmful substances and recover water for reuse.

Pharmaceutical Industry: Managing effluents that include active pharmaceutical ingredients, solvents, and other bioactive chemicals.

Food and Beverage Industry: Treatment of organic waste and food solids from production processes, reducing BOD and COD levels significantly.

Chemical Manufacturing: Handling effluents containing acids, bases, solvents, and other hazardous chemicals, ensuring that they meet safety and environmental standards.

Paper and Pulp Industry: Reducing the impact of pulping and bleaching operations by treating high volumes of chemical-laden water.

Leather Tanning Industry: Treating wastewater containing tanning chemicals and organic matter to prevent environmental contamination.

Metal Industry: Removing heavy metals and other pollutants from wastewater produced during metal processing and fabrication.