Coagulation and Flocculation: The Foundation of Effective Water and Wastewater Treatment

Coagulation and flocculation are among the most fundamental and critical processes in water and wastewater treatment. Regardless of whether a system uses conventional clarification, Membrane Bioreactor (MBR), Moving Bed Biofilm Reactor (MBBR), or advanced filtration technologies, these two processes play a central role in removing suspended solids, turbidity, and organic contaminants.

Understanding how coagulation and flocculation work allows operators, engineers, and decision-makers to select the right treatment strategy, optimize system performance, and protect downstream equipment.

Why Coagulation and Flocculation Are Essential

Raw water and wastewater typically contain fine suspended and colloidal particles such as clay, organic matter, cement fines, and biological solids. These particles remain suspended because they carry a negative surface charge, causing them to repel each other and resist natural settling.

Filtration alone cannot remove these particles effectively. Coagulation and flocculation solve this challenge by destabilizing the particles and allowing them to combine into larger, removable clusters. Without these processes, downstream units such as clarifiers, membranes, and filters would overload, foul rapidly, and fail prematurely.

What Is Coagulation in Water Treatment

Coagulation is the chemical process in which a coagulant is added to water to neutralize the electrical charges of suspended particles. Once neutralized, the repulsive forces between particles are reduced, allowing them to come closer together.

This step occurs rapidly and typically involves intense mixing to ensure uniform chemical distribution. Common coagulants used in water and wastewater treatment include:

Aluminum sulfate (alum)

Ferric chloride

Ferric sulfate

Polyaluminum chloride (PAC)

Once added, these chemicals react almost immediately, initiating the formation of destabilized particles that can begin clustering.

What Is Flocculation and Why It Matters

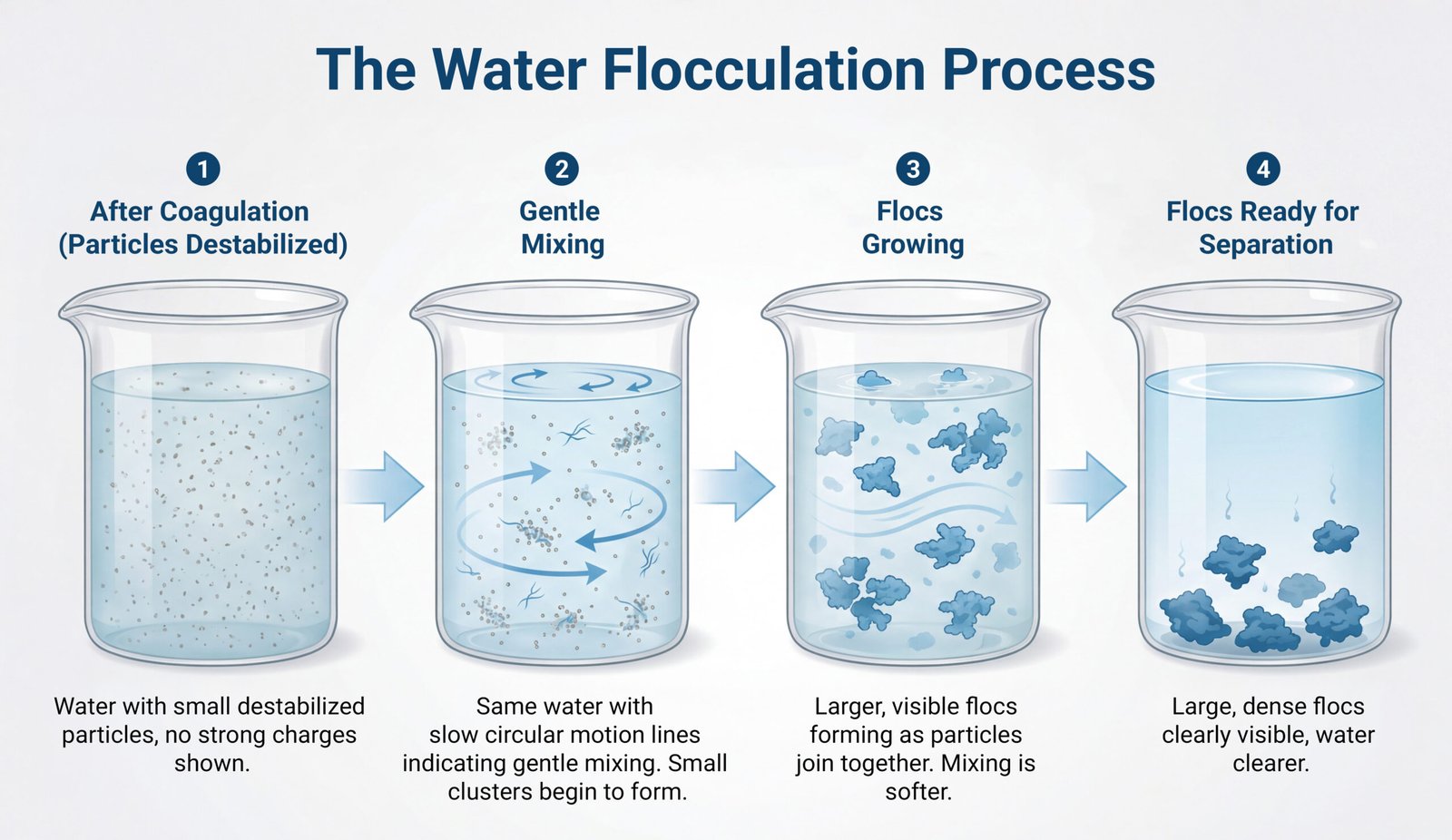

Flocculation follows coagulation and involves gentle, controlled mixing that allows destabilized particles to collide and bond together. During this phase, micro-sized clusters grow into larger, heavier flocs.

Flocculation improves overall treatment efficiency by:

Enhancing suspended solids removal

Reducing sludge volume

Protecting downstream equipment from fouling

Stabilizing effluent quality

In many systems, polymer-based flocculants are added to strengthen particle bonding and improve floc strength.

Coagulation and Flocculation: Step-by-Step Process

Step 1: Raw Water With Suspended Particles

At the initial stage, raw water or wastewater contains fine suspended and colloidal particles that remain dispersed due to their negative surface charge. Gravity alone cannot remove these particles.

Step 2: Coagulant Addition and Charge Neutralization

A coagulant is added under rapid mixing conditions to neutralize the electrical charges on suspended particles. Once neutralized, the particles lose stability and begin interacting.

Step 3: Particle Destabilization and Micro-Floc Formation

Following charge neutralization, particles collide and form small clusters known as micro-flocs. Proper control at this stage is critical, as poor dosing can lead to inefficient floc formation and excessive chemical usage.

Step 4: Flocculation and Large Floc Formation

Gentle mixing allows micro-flocs to grow into large, visible flocs. Flocculants such as anionic, cationic, or non-ionic polymers may be added to improve floc strength.

These flocs can then be removed by sedimentation, flotation, or membrane filtration.

Why Chemical Selection and Process Control Matter

Selecting the right coagulant and flocculant and applying proper dosing and mixing control directly impacts treatment performance. Poor chemical selection can result in:

Unstable pH

Excessive sludge generation

Membrane fouling

Increased operating costs

Modern treatment systems aim to optimize coagulation and flocculation to achieve consistent results with minimal chemical dependency.

Coagulation and Flocculation Across Treatment Technologies

Coagulation and flocculation are applied across nearly all treatment systems:

Conventional plants: Support sedimentation and clarification

MBR systems: Reduce membrane fouling and stabilize biological treatment

Industrial and concrete wastewater treatment: Remove high solids, cement fines, and heavy contaminants

Poor control at this stage can lead to inconsistent effluent quality regardless of the technology used.

Moving Toward Safer and More Sustainable Treatment

Traditional coagulation methods often rely on strong acids and alkaline chemicals for pH control. While effective, these increase corrosion risks, operator hazards, chemical transport emissions, and long-term costs.

Modern treatment philosophies focus on optimized dosing, biological stabilization, and safer pH control methods. Based on experience across 600+ projects in the GCC, Almasa has found that improving coagulation and flocculation control significantly enhances plant reliability, reduces chemical usage, and extends equipment life.

The Takeaway

Coagulation and flocculation are not optional processes they are the foundation of effective water and wastewater treatment. When properly designed and controlled, they protect downstream systems, improve efficiency, and reduce long-term operating costs.

As the industry moves toward safer, more sustainable, and low-carbon solutions, rethinking how these processes are applied will shape the future of water treatment in the GCC.

What is concrete wastewater treatment?

Concrete wastewater treatment is the process of removing cement fines, suspended solids, high alkalinity, and contaminants from wastewater generated by concrete batching and ready-mix plants. The treated water can be safely reused or discharged in compliance with environmental regulations.

Why is concrete wastewater treatment important for ready-mix plants?

Concrete wastewater treatment is essential for ready-mix plants to meet environmental compliance, reduce freshwater consumption, avoid regulatory penalties, and lower operational costs by reusing treated water within plant operations.

Can treated concrete wastewater be reused?

Yes. Properly treated concrete wastewater can be reused for non-potable applications such as truck washing, equipment cleaning, batching operations, and yard washing—significantly reducing freshwater demand.

How does concrete wastewater treatment help reduce costs?

Concrete wastewater treatment reduces costs by minimizing freshwater usage, lowering wastewater disposal expenses, decreasing sludge handling requirements, and preventing environmental fines or operational shutdowns.

Is concrete wastewater treatment mandatory in the UAE?

Yes. UAE environmental authorities require concrete and construction facilities to treat wastewater before discharge or reuse. Non-compliance can result in fines, legal action, or plant suspension.

What contaminants are removed during concrete wastewater treatment?

Concrete wastewater treatment removes:

Cement particles and fines

High Total Suspended Solids (TSS)

Elevated pH levels

Sand and aggregate residues

Chemical additives from concrete production

How long does a concrete wastewater treatment system take to install?

Installation timelines vary based on plant size and wastewater volume, but most concrete wastewater treatment systems can be installed and commissioned within a few weeks with minimal disruption to operations.

Why choose Almasa Environmental Solutions for concrete wastewater treatment?

Almasa Environmental Solutions offers customized, locally engineered concrete wastewater treatment systems with proven installations across the UAE and GCC, providing reliable performance, regulatory compliance, and long-term cost savings.