Table of Contents

Gold Medal in Sustainability: The Paris Olympics’ Blueprint for Clean Water Management

By Sourav Sripathi – Pennsylvania State University

Environmental Engineer, 054 586 4084

Introduction

The Paris Olympics, officially known as the Games of the XXXIII Olympiad, took place from July 26th to August 11th, 2024. This event marks the return of the summer olympics to Paris, since 1924. This also makes it a centennial celebration.

Significance:

Hosting the Olympic Games has been a long-standing tradition in promoting sports, and international unity, because it highlights the French culture, arts, and lifestyle, with various venues across iconic locations in the city, including the Seine River, which hosts events like swimming and rowing. In 2024, they focussed on a new goal: sustainability, aiming to reduce carbon footprints, and using existing venues, with global efforts toward environmental responsibility.

This event also incorporated new sports to promote inclusivity, with a commitment to gender equality in team composition, and event participation. Essentially, hosting the event created new opportunities to boost local economies, create jobs, and enhance tourism within their respective region. Overall, the Paris Olympics represent not just a celebration of athletic excellence, but also a commitment to cultural exchange, sustainability, and social progress.

The role of Wastewater Treatment in Events

Water is needed in all aspects of life, whether it be for drinking, or for irrigating plants. The importance of water doesn’t touch our lives completely, because of the advanced technology available to produce such water quality. However, a question we should ask ourselves is what happens to the water we don’t use?

In this regard, I refer to the wastewater produced primarily by people after domestic utilities. On average, each person produces 120 liters per day of wastewater. With approximately 15 million visitors adding on to the 12 million indigenous people, the wastewater produced by the whole country can reach up to 5 million cubic meters per day. A large portion of the wastewater is treated, and reused for irrigation purposes, and discharged into the river Seine. However, according to history, much of this wastewater was also discharged directly into the river, along with industrial waste. This makes rowing, and swimming on this river very dangerous.

It is possible to take back what is lost in the wastewater, and still reuse the water. This is the idea of water recycling, which falls under the wider umbrella of sustainability. Some effective reuse of treated water (TSE) are: irrigation, toilet flush, and vehicle washing. The solid waste produced in the process can also be reused for various purposes including: biogas generation, and agricultural fertilizer.

To ascertain the global objective of sustainability, great efforts were taken to treat the river water, contributing to the grand success of the Parisian Olympics. Safety procedures, and testing were implemented before the water games began.

Innovative Wastewater Treatment Technologies

In the past, water and wastewater treatment was a practiced tradition, especially within the Indus Valley Civilization. Their drainage systems were structured in such a way that it was directed to areas where it could be treated naturally. This was a biological treatment involving sedimentation, and absorption before entering water bodies.

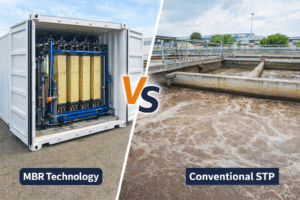

In the present, wastewater treatment has introduced some of the most innovative, and powerful technologies capable of handling challenges that a whole country can face. Some of these innovative technologies include: Membrane BioReactor (MBR), Moving Bed Biofilm Reactor (MBBR), Sequential Batch Reactor (SBR), and most recently Metabolic Network Reactor (MNR).

MBR technology

– first introduced in the 1960s, had trouble keeping up with large capacities of treatment, however, it was not until it advanced in efficiency, that allowed the first large scale treatment plant to be manufactured in the United States. Today, MBR technology has progressed so rapidly, that its initial skepticism on its efficiency and cost has more or less dissolved, because of easier manufacturing processes, and ultra filtration capabilities. There are two kinds of membranes that are used today, known as hollow-fiber, and flagsheet. These membranes rely on the process of suction, and ultrafiltration to screen out contaminants.

Hollowfibre membranes (Almasa Manufacturer)

Manufactured by Almasa Environmental; these membranes rely on the power of suction, and ultrafiltration to “pull” the water out of the wastewater. This allows for the formation of activated sludge on the membrane, making it that much more effective in biological treatment when employing an RAS (Recycled Activated Sludge). It effectively works like thousands of straws undergoing suction with pores scattered across its surface. These pores can have a size between 0.01 and 0.03 micrometers, reducing any chances for pathogens to pass through.

Image 1 Image 2

A microscopic view of the membrane depicts the distribution of pores within. Image 1 illustrates how the water travels into the membrane while leaving the debris and contamination behind. Image 2 is a diagrammatic view of how the filtered water is absorbed through the pores of the membrane in the same way.

There can be as many as 10,000 fibers within one curtain of membrane, allowing for filtration capacities up to 20 LMH (Liters/meter-squared . hour) in adverse conditions of wastewater. Typically, multiple curtains are installed for medium-large capacity plants – resulting in larger volumes of treated water produced, and less than 1% of the capacity treated as sludge produced in the process.

Image 3

Flagsheet membranes

It is a composite membrane structure made of the following materials: PVDF (polyvinylidene fluoride) or PTFE (Polytetrafluoroethylene), and PET (Polyethylene terephthalate) – non woven fabric to increase the stability, and chemical resistance.

Image 4

The process works in a similar manner to hollow-fiber membranes, but can tend to produce more solid-waste material, such as sludge if it’s not compatible with an RAS (Recycled-Activated Sludge) system. However, it’s efficient, and economic to use in place of UF (Ultrafiltration membranes), because it takes up less space.

MBBR Technology

A very widely used technology for water, and wastewater treatment, this technology has maintained its reputation for being a traditional, yet efficient method of treating wastewater. This technique has been used for treating medium-large volumes of wastewater through the usage of biofilms. MBBR (Moving Bed Biofilm Reactor) relies upon the growth of bacterial biofilms on special media to treat wastewater.

Image 5

When employing MBBR technology, it requires additional pretreatment processes such as flocculation to remove suspended solids from the water in addition to the media filters. Image 6 depicts an Anoxic tank in addition to the MBBR process. In some cases, more chemicals are needed for sedimentation processes. This impacts the footprint, cost, and power consumption of the plant, but is still heavily regarded, and relied on as an ‘old but gold’ solution in wastewater treatment.

Image 6

MNR

This is one of the latest, and most innovative technologies known as Metabolic Network Reactor (MNR). In layman’s terms, it is the conceptual combination of MBR technology, and MBBR technology. It relies on biofilms forming on the roots of aquatic plants to facilitate bacterial, and chemical removal. To produce said biofilms, there needs to be a large amount of biomass attached to submerged carriers – either to the root system of specially selected plants, artificial membrane roots, or a combination of both. Each reactor is divided based on the species of plant and their role in treating the wastewater. A particular species can remove the BOD faster than the COD as an example. The path and volumetric distribution of wastewater between the reactors is controlled by process management software and can dynamically adapt to the changing loads, thereby optimizing the process.

Public Awareness and Education

Paris has significantly invested in upgrading its wastewater treatment facilities to meet the increased demands posed by the Olympics while enhancing efficiency. With the implementation of green technologies in treatment plants, such as energy recovery systems and eco-friendly processing methods. By also establishing robust remote monitoring systems, they were able to track the effectiveness of wastewater treatment processes with the usage of SCADA. Its impact on local water quality has been a successful initiative.

The city also launched campaigns to inform both locals and visitors about the importance of water conservation and proper waste disposal, tying into the Olympic theme. Their collaborations with NGOs and environmental groups helped raise awareness and ensure that sustainability remains a priority throughout the event. These initiatives included how biogas, and fertilizers can be produced from wastewater treatment plants through advanced filtration techniques.

With the usage of these enhanced wastewater treatment systems, they don’t only tackle water pollution, but climate change as a whole. The emissions produced from these plants are significantly lower, and the solid waste produced is also used in production of biogas. This means that rainfall will be less acidic in nature, and carbon emissions will be much lower, resulting in less contribution towards global warming.

Conclusion

With the grand success of the olympics, Paris was not only able to host one of the greatest events in the decade, but create a new wave of sustainability within its citizens and those who had attended. By utilizing advanced water treatment technologies, river Seine turned from a hazardous zone to a swimmer’s playground, allowing for many sustainability campaigns to also take place during this time. This goes to show that sustainability does not have a price. It only has a future.