Introduction

Wastewater is not a waste till it’s wasted. This statement has been embraced by past civilizations like: Indus Valley, and Egyptian civilizations in the past with the use of ancient filtration technologies that had proven efficiency. This is because all living creatures understand the value of water in important biological processes, whether it be a dietary or hydration need. In the present, we embrace modern filtration processes; like MBBR, and MBR technologies to transform waste to value. Under the presumption, that you as the buyer are looking to treat wastewater; this article looks to assist you with criteria to follow to effectively plan your wastewater treatment needs.

Application and Consumption

In the UAE, water consumption is on the rise, given the speed of development of different industries. A vision has been imposed for the year of 2030, where sustainable development of each industry must reach its peak. One cause to realize this goal is through sustainable wastewater treatment. However, it’s important to understand the source of the wastewater to apply any treatment processes.

Sewage Wastewater

This is the most common type of wastewater that is discharged from accommodations, hotels, and residential areas. This wastewater is characterized by the following parameters:

| Parameters | Numeric Value (mg/L) |

| pH | 6.0 – 9.0 |

| BOD | 300 |

| COD | 400-500 |

| TSS | 250-300 |

| TDS | 600-1,100 |

Treating sewage water requires a process design capable of handling large volumes of wastewater; including shock-loads. Shock-loads are large volumes of wastewater that exceed the capacity of the treatment plant. Normally, all plants can handle these shock-loads, however; in the event that the design is insufficient, a pungent smell will arise from the treatment plant. This is why an accurate study of the capacity must be taken into account before commencing the design. A common design involves the physical screening process, aerobic or anaerobic aeration, and filtration process. Bar screening is used to segregate larger pieces of plastic, and wood. Aeration is used to promote or reduce the growth of bacteria depending on the chosen filtration process. Filtration processes include: SBR, MBBR, ASP, and MBR processes to filter waste from wastewater to produce TSE water usable for irrigation.

Effluent Wastewater

Effluent wastewater is wastewater discharged from factories, and Industrial complexes. Treating such wastewater often requires special treatment processes depending on its parameters. A thorough testing of this wastewater, along with the exact capacity must be considered before commencing design. In some facilities: sewage water is often mixed with the factory effluent as an attempt to counterbalance the high parameters of effluent. This process, although successful, would still require a thorough testing.

| Parameters | Numeric Value (mg/L) |

| pH | 5.0 – 9.0 |

| BOD | 8,000 |

| COD | 20,000 |

| TSS | 200 |

| TDS | 2,000-2,500 |

Treating effluent wastewater requires advanced pre-treatment processes such as DAF (Dissolved Air Flotation). This is an efficient system capable of handling most factory effluents, followed by an aerobic or anaerobic as well as a chosen filtration process, such as: MBBR, SBR, and MBR.

Greywater

Greywater is a type of wastewater that is produced by all streams of wastewater except the toilet flush. The presence of BOD is lesser than in sewage, this wastewater is often seen as a cleaner wastewater when compared to sewage, however both types have relatively similar qualities.

This wastewater, based on the approximate parameters listed below, makes biological treatment very versatile in nature due to the ratio between BOD, and COD coming closer to 1.0.

| Parameters | Numeric Value (mg/L) |

| pH | 6.0 – 8.0 |

| BOD | 150-200 |

| COD | 200-250 |

| TSS | 100-150 |

| TDS | 600-1,100 |

Pre-treatment

An important step within the wastewater treatment process used to reduce the parameters of given wastewater from a high concentration to a value the filtration unit can be able to handle without issues.

There are many different processes of pre-treatment that are used in the above manner whether it is used in biological or mechanical systems.

Screening

This is the process whereby larger solids are separated with the use of a mesh screen. The size of the mesh is designed to remove large pieces of wood, and plastics.

Oil/Gas Separation

A treatment process used to segregate oil from wastewater typically arriving from kitchens. A grease trap is always placed before stored, discharged, or treated. This process is also viable in operations where there is a large amount of oil, such as: car wash – water treatment, food factory effluent.

Dissolved Air Flotation (DAF)

This remarkable system is responsible for the efficient removal of suspended matter, such as: oils, and solids. The feed water is often dose with a coagulant, and flocculant to coagulate and conglomerate particles into suspension. This makes said particles easier to remove mechanically. Common coagulants include: Ferric Chloride (FeCl3), and Aluminum Sulfate (Al2(SO4)3)

Filtration Technologies

Filtration is an important step in the process of water/wastewater treatment, because it facilitates the complete removal of chemical, and biological contaminants. There are many proven filtration technologies that have been implemented in the last century. This article will cover conventional, and modern filtration methods.

Sequential Batch Reactor (SBR)

This technology uses a batch process, by segregating volumes of the wastewater for each process, including: equalization, aeration, and clarification. Since wastewater is processed at a particular stage, this allows for lower maintenance, and low power consumption. The method for SBR is using a fill and draw system for the activated sludge to increase levels of bacteria and consume chemicals within the aeration step. This allows for water to be separated from contaminants as depicted in the diagram below.

Depending on the application of the wastewater, the waste sludge is often recycled and reused in the first step of the SBR process. For treating sewage wastewater, waste sludge that accumulates over time is recycled, however for wastewater that contains a large amount of chemicals, it is not recommended to recycle that sludge because of the vast amount of concentrated chemicals.

Moving Bed Biofilm Reactor (MBBR)

One of the pinnacle water treatment technologies in the late 1970s, invented by Dr. Harvard Degaard at Norwegian University of Science and Technology. There are special media known as ‘plastic carriers’ that facilitate the growth of bacterial biofilm. The bacteria assist with degrading chemicals within the wastewater allowing for treated water to have low chemical and bacterial content.

MBBR filtration is a proven technology that is continuously improved with conventional methods such as activated sludge recycling. This enables the system to produce treated water of high quality, but comes at the expense of operation cost, power consumption, and the footprint of the plant. For example: the operators must be very familiar with the processes in this system, given that it can become more complex for industrial wastewater.

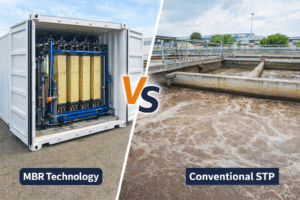

Membrane Bioreactor (MBR)

First developed in the 1960s, this technology has undergone continuous research into making it more affordable in countries with limited water resources. In the UAE, MBR technology was used very sparingly for projects that were treating smaller capacities of wastewater. However, due to its manufacturing cost being more economical, it’s now possible to integrate it in large projects that can exceed over 1,000 cubic meters per day.

MBR technology, much like other biological treatment processes, functions as a filtration stage to prevent bacteria from passing through the membrane. Its pore sizes can range between 0.03 micrometer to 0.1 micrometer, which completely prevents bacteria from passing through.

The aeration step within the STP fuels the growth of bacteria within the wastewater, and the activated sludge recycling process enables a further increase in bacteria within the wastewater. This allows for the swift decomposition of chemicals in a continuous process. It is through suction from the membrane, that clean and treated water is produced.